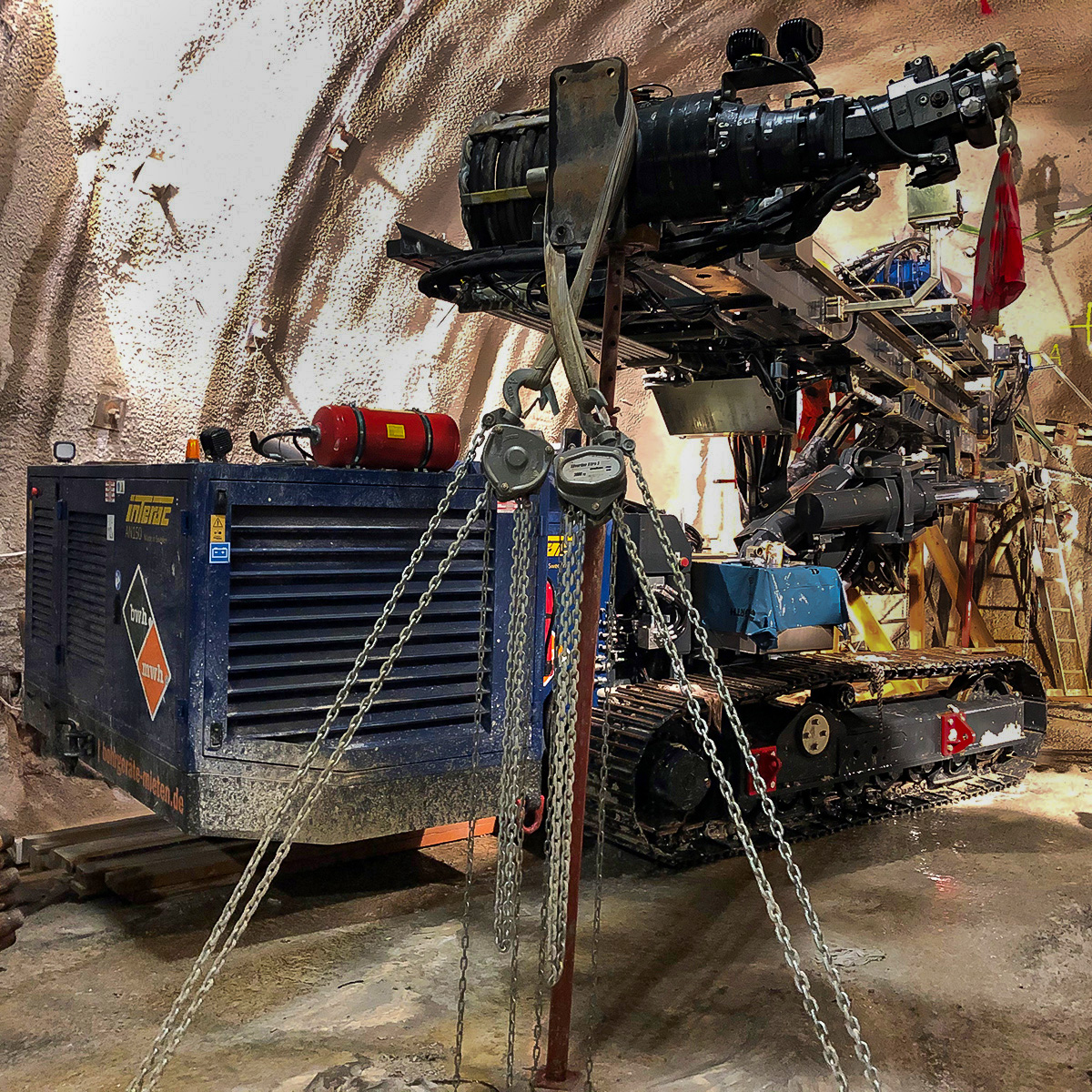

Der Umbau von Bohrgeräten zu diversen Low-Head-Varianten durch temporäres Einkürzen des Mastes...

Diese Website verwendet Cookies, um Ihnen eine bestmögliche Benutzerfreundlichkeit bieten zu können. Cookie-Informationen werden in Ihrem Browser gespeichert und führen Funktionen aus, wie z.B. die Erkennung, wenn Sie zu unserer Website zurückkehren, und helfen unserem Team zu verstehen, welche Bereiche der Website Sie am interessantesten und nützlichsten finden.

Sie können alle Ihre Cookie-Einstellungen anpassen, indem Sie auf den Registerkarten auf der linken Seite navigieren.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

You can adjust all of your cookie settings by navigating the tabs on the left hand side.